Technical Solutions

TYK is offering technical solutions to our customers like the TN-A1 Sliding Gate System, the Gas Holder System for the steel ladle or the Flow Rate Detector tool for the flow control of the purging plug during O2 cleaning.

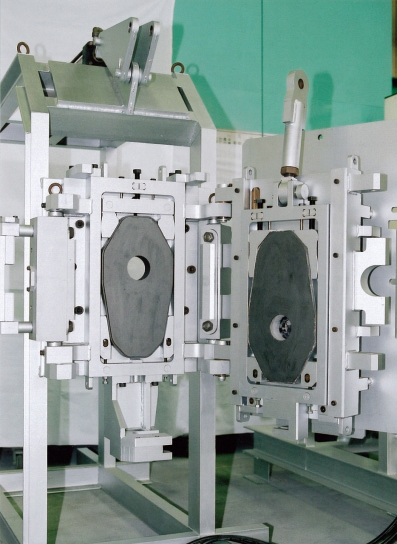

Ladle Gate System TN-A1

Our TN-A1 sliding gate system is a simple user friendly ladle gate system. We combined and optimized the advantages of different systems in the TN-A1. Today we have 2 versions in use, one with a maximum bore size of 80 mm and one with 100 mm.

Main Features

user friendly setting and release of face pressure

easy and tight fixing of the plates with only one bolt

easy installation at the ladle

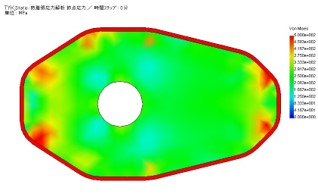

fixing of the plate from 4 directions to reduce thermal stress and to prevent open cracks

TN-A1 Gate

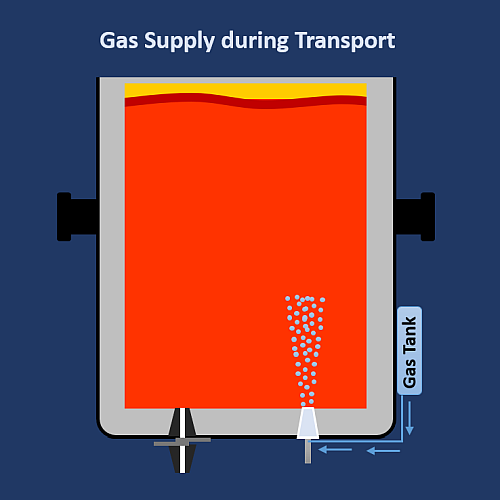

Gas-Holder System

TYK has developed a gas tank for the ladle to increase the efficiency and durability of the purging plug. This tank supplies the plug with gas during the moving times of the ladle. This prevents the plug to clog during the treatment times, easier cleaning due to no metal penetration and keeps some stirring during this periods. The result is an increased life of the plug, better restart of blowing after transport and an positive effect for the steel quality.

Ladle with Gas Tank

Advantages of the "GHS"

Longer life of the plug due to reduced O2 cleaning

Prevention of clogging during treatment campaigns

Positive effect for the steel quality due to constant stirring

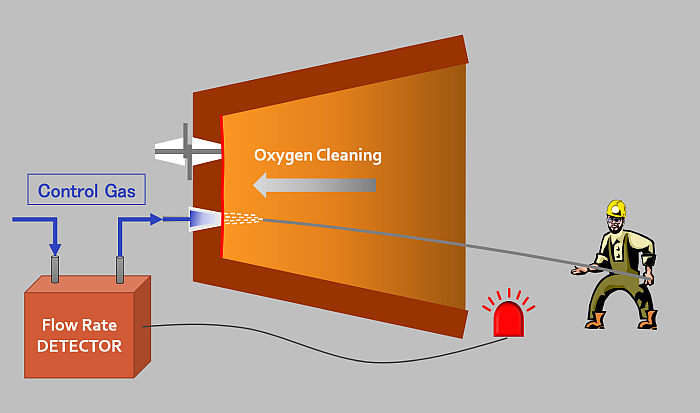

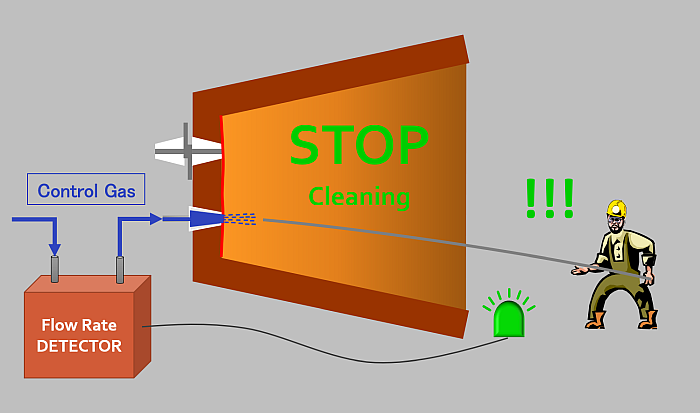

TYK "Flow Rate Detector“ for optimized O2 cleaning

The uncontrolled O2 cleaning of the purging plug leads often to a reduced lifetime of the plug. The use of the „Flow Rate Detector“ can prevent this. The detector indicates the worker that the sufficient flow rate is reached and the cleaning can be stopped. Through this, the lifetime of the plug can be increased significantly.